Inspections

When do we come out to inspect?

Based on what is required by the energy or code checklist, we inspect at different stages of construction.

Phase 1 - Frame - Pre-Insulation

Phase 1 - Frame - Pre-Insulation

Phase 1 - Frame - Pre-Insulation

- Air sealing/barriers in place

- Backing behind tubs and showers installed

- Plumbing, mechanical, and electrical installed with penetrations sealed

- HVAC duct work, systems, and ventilation completely installed and sealed

- Lath complete

- Bottom plates of exterior walls caulked to slab

Duct testing can be preformed

Phase 2 - Rough - Pre-Drywall

Phase 1 - Frame - Pre-Insulation

Phase 1 - Frame - Pre-Insulation

- Insulation must be installed completely with no voids, compression, or empty cavities

- Any Phase 1 items that can be verified will be checked

Phase 3 - Final

Phase 1 - Frame - Pre-Insulation

Phase 3 - Final

- A/C equipment completely installed and operable

- A/C startup complete

- Fresh air ventilation timer switch (if applicable) set-up and programmed

- Doors, flooring, exhaust fans, and kitchen exhaust installed and operable

- Trade interruptions must be minimal, especially painters because doors must be closeable for extended periods of time

Duct testing & Blower Door can be preformed

Field Testing

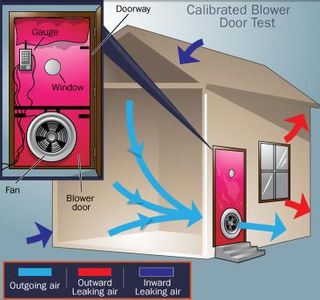

Blower Door / Envelope Leakage Test

A blower door is a powerful fan that mounts into the frame of an exterior door. The fan pulls air out of the house, lowering the air pressure inside. The higher outside air pressure then flows in through all unsealed cracks and openings.

These are some reasons for establishing the proper building tightness:

- Reducing energy consumption due to air leakage

- Avoiding moisture condensation problems

- Avoiding uncomfortable drafts caused by cold air leaking in from the outdoors

- Determining how much mechanical ventilation might be needed to provide acceptable indoor air quality.

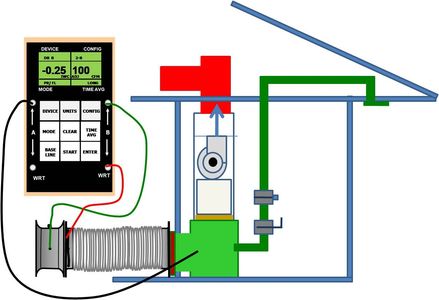

Duck Leakage

Two types of tests are performed: total duct leakage and leakage to the outdoors:

- “Total” duct leakage test - measures how much leakage there is for all of the ductwork connected to the HVAC system, including ducts located both outdoors and indoors.

- "Duct leakage to the outdoors" - test measures only duct leakage outside of the home’s air barrier, i.e., leakage to the outdoors, for example, into an unconditioned attic or crawlspace.